Seeking Plastic Machining Near Me?

Plastic machining near me is a versatile process that stands out for its efficiency. CNC plastic machining allows for a high-volume of complex plastic parts to be manufactured quickly thanks to its technical computer programming.

CNC stands for computerized numerical control, which means that this equipment can automate multiple fabrication tasks. This is different from plastic injection molding, which is another plastic manufacturing process that produces parts from molds.

When you’re seeking plastic machining near me, it helps to know the difference between these two plastic production processes. Let’s take a look at some main differences.

CNC Machining | Plastic Machining Near Me

As mentioned, CNC machining is great for producing large volumes of complex parts. The efficiency of this process is what makes it a leading solution for plastic machining near me. CNC machining uses computer controlled cuts to remove material from a block, one layer at a time. As the material is removed and refined, the block grows closer to the final product.

In order to remove the material properly, CNC machining pulls this information from a CAD file that has the directions for which alterations to make. The computer takes these directions and breaks them down into simple commands which are then fed to the milling tools that are used to create the final product.

If this sounds complex, it isn’t. This type of plastic machining near me is all about quick and effective communication between the computer and the milling tools. What makes CNC machining so widely used is actually its simplicity; making long, specialized directions into simple, short commands. Once connected, these commands are used to create a complex, specialized plastic part. This plastic machining near me is great if you have a niche plastic part you need to create at a high volume.

The Plastic Injection Molding Process

Plastic injection molding, per its name, uses molds to create plastic parts. During this process, molten plastic materials are injected into a mold, and then into the part itself. Before being injected, the plastic must be heated in the barrel, then injected into the mold, and then it moves along channels until it’s inserted into the part.

At the end of the plastic injection molding process, the mold opens and the part is ejected. That’s when the process can repeat itself again. Although this process is different from plastic machining near me, it is still a fast way to create plastic parts. What you need to speed up this process is a hydraulic or electric machine, an accurate mold, and quality plastic resin. Most often, you’ll find this level of quality at a plastic manufacturer near me who has the resources to run an efficient plastic molding process.

About Jaco Products

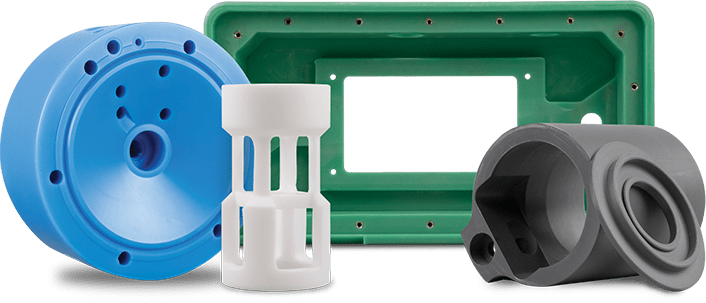

Jaco Products is a manufacturing expert when it comes to plastic machining near me. In fact, they are the largest supplier of thermoplastic injection molding services, plastic machining, and plastic stamping. Jaco Products’ has an extensive portfolio of niche, specialized parts most manufacturers would turn away from.

They have a state-of-the-art facility full of innovative equipment that completes jobs quickly and efficiently. Their ever-growing customer base is a testament to their outstanding service, competitive pricing, and quality parts. On every single project, Jaco Products uses computer-aided CAM and CAD manufacturing programs to ensure their products pass through their rigorous quality control standards.

Ready to work with the #1 plastic machine shop and get quality plastic machining near me? Visit https://jacoproducts.com/ to learn more and get started.

Featured client/products:

Vault Lights | Yard Ramp | Glass Bricks | SEO Services Near Me

Glass Floors | Semi Truck Ramp | Glass Blocks| SEO Services Near Me | Steel Yard Ramp | Ramp for Loading Dock | Glass Flooring | Loading Dock Ramps

SEO for Manufacturers | Manufacturing SEO Agency

Featured client/products:

Portable Yard Ramp | SEO Agency Akron | SEO Expert Near Me | Marketing Agencies Near Me | Marketing Agency Akron

Yard Ramps