What Are the Different Types of High Temperature Thermal Insulation? | Plastic Components Company

A plastic components company produces high temperature thermal insulation for various applications, all with the same benefit: lower energy losses that lead to great efficiency and better returns on investments. Whether the insulation is used in residential cavity walls or shielding mechanics from high temperatures, high temperature thermal insulation all has the same purpose.

Before discussing the various types of high temperature insulation materials, it’s important to understand some of the basic concepts of thermal conduction and insulation from plastic machining suppliers. Heat is a thermodynamic quantity of thermal energy that flows from one system to another when there is temperature difference between the two. Heat can be transferred via one of three different methods: conduction, convection, or radiation.

High-Temperature Applications | Plastic Components Company

It’s important to select a thermal insulation material from a plastic company near me that can withstand the intended application. Typical applications that experience high temperatures include:

- Furnaces and boilers

- Ovens and kilns

- Expansion joints

- Flanges

- Heat exchangers

- Compressors

- Turbines

- Chillers

- Incinerators

- Catalytics converters

- Engine and exhaust components

- Welding

- Dryers

- High-pressure steam piping

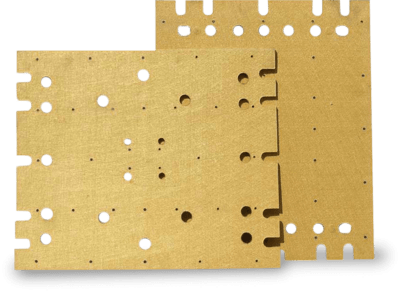

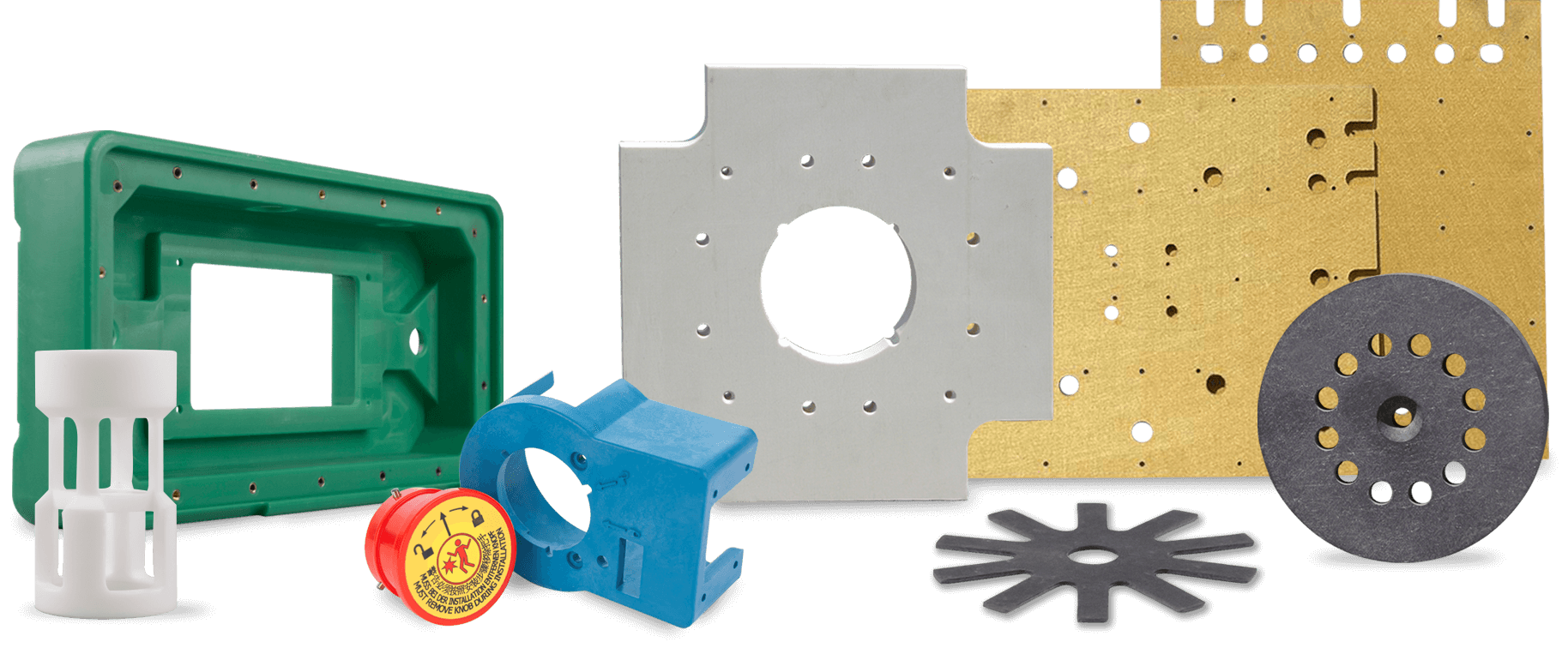

High-Temperature Insulation Materials From a Plastic Components Company

- Fiberglass – Fiberglass provides excellence flexibility and dimensional stability for temperatures up to 1200°F. It is also user friendly with little odor or smoke, ensuring it will not corrode the metals it protects.

- CMS Wool – CMS wool is typically more expensive than fiberglass and can withstand temperatures up to 2192°F.

- Super Wool – Due to a distinctly lower biopersistence, super wool requires fewer safety and health requirements while managing the material.

- Ceramic Fiber – This material is inorganic, smoke-free, and has above-average insulation properties, low heat storage capacity, low thermal conductivity, and dependable thermal shock resistance.

- Polycrystalline Fiber – Polycrystalline fiber is made primarily of aluminum and silicon, and is created by using sol-gel technology. Double-needed fibers make the polycrystalline extremely durable and flexible.

Selecting the Best Thermal Insulation From a Plastics Components Company

There are many factors to consider when choosing high-performance thermal insulation materials for your specific application. A few key components to keep in mind include:

There are many factors to consider when choosing high-performance thermal insulation materials for your specific application. A few key components to keep in mind include:

- Thickness Tolerance: Determine the desired thickness of the thermal insulation sheet or material. A tight thickness tolerance of the material keeps the temperature of the mold more uniform.

- Temperature: Consider the temperature of your application and what level of resistance the thermal insulation material requires. Many thermal insulating materials can vary in temperature resistance.

- Thermal Conductivity: Thermal conductivity is the degree to which a material can conduct electricity. Conductivity is determined as the ratio of current material density to the electric field that causes current flow.

When you need thermal insulation materials from a reliable plastic components company, choose the best plastic fabrication company in Cleveland. Make sure to do your research about who is the best thermal insulation provider in your area. They should provide numerous options for materials application processes to engineer the exact materials you need.